A Tiny Piece of Plastic Is Helping Farmers Use Far Less Water

- Get link

- X

- Other Apps

An Israeli company’s modest innovation in drip irrigation could forever change agriculture, especially in resource-starved environments.

On the bone-dry western flank of Arizona, where the Colorado River Basin meets the Mojave Desert, sit 11,000 acres of alfalfa, sorghum, wheat, and Sudan grass belonging to the Colorado River Indian Tribes (CRIT), all destined to be harvested and sold for animal feed. For anything to grow here, irrigation is a must. Less than a quarter inch of rain has fallen so far this year, according to Josh Moore, who manages the farm on behalf of his tribe.

“The reservation is set up on a pretty outdated flood irrigation system,” Moore says. A network of canals built in the 19th century delivers water from the Colorado River, a system that seemed like a better idea before the watershed entered a persistent and increasingly dire state of drought. Although the canals supply enough water to meet CRIT’s farming needs for now, the tribes are planning for a hotter, drier future. This season, black plastic tubing can be seen snaking down hundreds of rows of sorghum: an experiment with microdrip irrigation that could radically reduce the farm’s withdrawals from an overtaxed watershed.

Around the world, most crops depend on rain alone for their water, but in places where rainfall isn’t sufficient, we’re forced to irrigate. Despite all the innovation that’s made its way into agriculture in recent years, from GPS-guided tractors to genetically engineered seedlings, 85% of all irrigation is still done by releasing vast quantities of water across the surface of a field, pretty much the same way it was handled 4,000 years ago in Mesopotamia.

Flood irrigation has hung on because it’s cash-cheap, but from a natural-resource perspective, it’s staggeringly expensive. As much as 70% of the water goes to waste, and overwatered crops can fail to reach their full potential. Excess fertilizer is carried away by the runoff, contaminating streams, wetlands, and lakes.

Microdrip irrigation was supposed to solve all that. In the 1930s, a young engineer named Simcha Blass noticed a tree that had grown much taller than the others in the same row; when he looked closer, he found that its roots were being fed by a tiny leak from a nearby irrigation pipe. Years later, the Israeli used the concept to create a plastic drip irrigation system that went on to be sold under the brand name Netafim. It remains the global leader in its sector.

Today, there are hundreds of drip irrigation companies, but the technology is being applied to less than 5% of irrigated acres globally, usually to big-ticket crops such as almonds, wine grapes, and tomatoes. The limiting factor is cost. As the systems are currently designed, pushing water through hundreds of feet of pipe requires a lot of force, which farmers supply with pumps; electric ones if they have power in their fields, carbon-belching diesel versions if they don’t. The dripper lines are also prone to getting clogged by silt particles or algae found in natural water, so it must be filtered, which adds another expense. The whole setup amounts to at least $2,000 an acre, plus energy bills. For lower-value crops such as cotton or alfalfa, drip irrigation simply doesn’t pay.

The microdrip setup being used by CRIT Farms, however, cost less than $400 an acre to install, and the required pressure is supplied entirely by gravity, which has the advantage of being free and carbon-neutral. To the casual observer, the system doesn’t look like much. But to Moore, the idea of drip irrigating crops for animal feed is nothing short of revolutionary. Assuming, of course, that it actually works.

“When the well’s dry, we know the worth of water,” Benjamin Franklin wrote in a 1746 edition of Poor Richard’s Almanack. He didn’t know the half of it. Today’s global population is 10 times what it was back then, and freshwater sources are in decline. The biggest water hog by far is agriculture, which accounts for almost three-quarters of global use.

Signs of water scarcity are all around us, growing more alarming with each passing year. In August, for the first time in history, the Colorado River was declared by the U.S. government to be in a state of shortage, triggering supply cuts to some of the 40 million people who depend on it. Five million of them get their water courtesy of the Central Arizona Project (CAP), a public utility that delivers river water by canal from the western edge of Arizona to 80% of the state’s population.

Chuck Cullom, the Colorado River programs manager at CAP, has spent the past decade exploring options for increasing Arizona’s water supply, including wastewater-treatment technologies and gadgets that help urban customers curb their use. In 2019, at a conference in Tel Aviv, Cullom met an executive from an Israeli irrigation startup called N-Drip, which was developing a system that promised drastic water savings without the prohibitive costs. “I was superskeptical,” Cullom says. “It sounded like a unicorn solution.”

But agriculture accounts for the vast majority of Arizona’s freshwater use, so Cullom was willing to try N-Drip. In 2020, CAP provided the system to CRIT Farms for use on 40 acres of sorghum. They found that it cut water use in half, while slightly improving the quality of the crops: a staggering result, albeit on a very small scale. This year, CAP expanded the pilot to about 200 acres of sorghum and cotton across Arizona, and, if all goes well, hopes to deploy the system regionally by 2023, continuing to cover the cost of the equipment for farmers who install it.

N-Drip is the brainchild of Uri Shani, a professor of soil physics at the Hebrew University of Jerusalem and a former chairman of Israel’s water authority. He set out seven years ago to devise a microdrip irrigation system cheap enough to make sense not just for lettuces and berries but also commodity crops such as soy and corn, which make up the bulk of the world’s agricultural output.

Shani is 72 years old, with short salt-and-pepper hair, wire-rimmed glasses, and an avuncular manner. He was born in 1950, on a kibbutz suffused with an angst peculiar to life in an arid country committed to agricultural self-sufficiency. “My father was an engineer who worked primarily on water. I grew up thinking about water and water solutions all my life,” Shani says, speaking by Zoom from N-Drip’s office in Tel Aviv.

After completing his military service with an elite commando unit, Shani went on to Hebrew University, Israel’s preeminent research institution, and got a master’s degree in soil physics. For his Ph.D. work, he moved to Kibbutz Yotvata, in the desert in Israel’s far south. The area gets less than an inch of rain each year and has only brackish groundwater for irrigation purposes: the outer limits of agriculture. He began there as a grad student and ended up managing the kibbutz.

Shani later became a professor, and in 2006 was tapped to become the first head of the newly created Israel water authority. The role was complex, spanning engineering, management, politics, and economics, and he took it on with the country experiencing its worst-ever drought. Shani turbocharged investment in water recycling and desalination. To pay for it, he significantly—and controversially—raised the price of water.

“Around the world, the reason why there are so many water problems is very few countries are prepared to charge consumers the real price,” says Seth Siegel, N-Drip’s chief sustainability officer and the author of a 2015 New York Times bestseller, Let There Be Water, that recounts Israel’s rise as a leader in water conservation and technology. In 2012, Shani left office with Israel in a freshwater surplus. “It was extraordinary what he pulled off.”

A private citizen once again, Shani began ruminating on the growing threat of water shortages worldwide. More than a quarter of the world’s population lives in water-stressed countries, and the United Nations estimates that water scarcity could displace 700 million people by the end of the decade. The most significant contribution he could make, he decided, would be to help drip irrigation go mainstream. That meant inventing a system that ran without filters and pumps.

To understand Shani’s challenge, you first must understand what’s happening inside those humble black plastic dripper lines. Along each one is a series of holes, and fastened inside every hole is a plastic widget about the size of a Tic Tac, called an emitter. Water moves through an exceedingly narrow, maze-like channel inside the emitter, regulated so it comes out in measured droplets. The resistance produced by those emitters is the reason so much pressure is required to move water from one end of a field to the other in a traditional system.

Shani conceived a new kind of emitter, one that offered so little resistance that the water pressure provided by gravity alone—accrued during the 1- to 2-foot descent from the irrigation canal to the field below—would be enough to propel the water all the way down hundreds of feet of tubing and out into the ground. First, he experimented with weaving plastic and metal fibers into various three-dimensional lattice structures. But it was on a hike one day, he says, that the breakthrough came: Instead of a zigzag channel, his emitter would consist of a rod suspended inside a cylinder, with water flowing through the tube shape formed between them. Unlike with a traditional emitter, now, no single particle of debris could block the water’s flow. “Boom,” Shani says. “I was absolutely convinced it would work. Then we developed all the mathematics.”

Once he fine-tuned the concept, Shani needed to commercialize it. He contacted Eran Pollak, a former finance ministry official with whom he’d worked closely as water chairman, and told Pollak he’d invented drip irrigation that used only gravity. Pollak was skeptical. He’d grown up on a kibbutz, too, and he knew about irrigation; there was no such thing as zero-pressure drip.

“My first reaction was, of course this would change the world, but it will never work,” Pollak recounts. He met Shani at N-Drip’s headquarters, which at the time was a small office in a strip mall in a Tel Aviv suburb. Shani led him to a shed out back. “It was 20 meters of pipe, manually glued together, dripping water on the ground from a small plastic garbage can,” Pollak says. “It was in the most elementary stage imaginable, but this was the minute in which I understood it could work.” Pollak signed on as chief executive officer.

N-Drip installed its first official field trial at the end of 2017, on five acres of sugarcane in Eswatini (formerly Swaziland), drawing water directly from a river. They found that the system not only worked and used less water but also increased crop yields by 30%. With encouraging results in hand, N-Drip moved on to larger trials in Australia and the U.S., and has since expanded to 17 countries, from Vietnam to Nigeria. If Shani’s vision bears out, N-Drip stands a chance at modernizing millions more farms, and transforming freshwater consumption globally.

To date, N-Drip has raised $25 million in funding, and its system is being used by hundreds of farmers for 4,000 acres’ worth of crops, ranging from cotton to potatoes to soybeans. But Shani has a long way to go if he intends to convert the Earth’s 600 million flood-irrigated acres, and the road from garden shed to global irrigation solution will have plenty of obstacles.

Because N-Drip doesn’t use filtration, most of the hiccups thus far have had to do with all the unexpected things one might find in water on a farm. Early in one trial, a California grower contacted N-Drip in a panic to say that his system had stopped functioning. When Shani arrived, he found a fish the size of his index finger clogging one of the pipes. A clump of green algae did something similar on a farm in Kazakhstan. Now, N-Drip’s water tanks are outfitted with mesh netting to capture all manner of plant and animal life.

In the baking sun of Arizona, in a region with particularly mineral-rich water, the dripper lines got so hot that calcium carbonate precipitated out, coating the emitters in limescale like the inside of a British teakettle. That led N-Drip to develop protocols for burying its lines in a thin coating of soil to keep them cool and for using softeners on hard water.

David Midmore, a professor emeritus of plant sciences at Australia’s Central Queensland University and an expert on microdrip irrigation, says that if N-Drip truly plans to reach the world’s 500 million small-scale farmers, and not just large, sophisticated growers, success depends not only on designing the right technology but also on investing substantially in education and support. “It’s very important that the growers be taught the correct ways to drip-irrigate, to have simple measures of water in the soil, and how not to over- or under-irrigate,” he says. “It’s not only training, but follow-up.”

N-Drip insists that small farms are a crucial part of its mission. “If a rich farmer in Australia increases yield by 47%, that’s great, pop open the Champagne, take a fancier vacation that year,” says Siegel, the company’s chief sustainability officer. “But if a subsistence farmer increases yield, and they have more food to eat and more food to sell, it transforms that family and that community.”

To that end, as the Covid-19 pandemic unfolded in 2020, putting lucrative projects in the U.S. and Australia on hold, N-Drip pivoted to manufacturing a 1-acre kit designed for these users. This DIY system arrives with a link to a YouTube video and simple, Ikea-esque line drawings to guide the farmer through installation.

N-Drip has also developed a proprietary soil sensor, called N-Drip Connect, that monitors plant and soil conditions and sends farmers real-time guidance via a smartphone app on when to irrigate and fertilize. The sensor feeds back to the company’s agronomic team, too, so that it can keep tabs on the field conditions.

Another challenge for N-Drip will continue to be economic. The system can be installed for a fraction of the cost of a conventional pressurized drip system, with none of the ongoing energy costs, but water is free or heavily subsidized for most farmers globally. Although some, such as Australian cotton growers, might be willing to invest to urgently protect a fast-dwindling resource, many of the world’s small farmers would be unable to cover even a modest additional expense.

“The smallholder market is a huge market, and one that can benefit most from our system, but it’s very difficult to do business with if you don’t have a large and well-positioned partner,” Pollak concedes. N-Drip envisions providing its system to these farmers primarily via nonprofits, government agencies, and large corporations making good on sustainability pledges. Its executives say the opportunity, in the near term, can be measured in hundreds of thousands of acres of agricultural land.

An early example of this sort of partnership is with PepsiCo Inc., which contracts directly with 40,000 farmers for ingredients such as corn, oats, and potatoes, and has set a goal of improving agricultural water-use efficiency by 15% by 2025. PepsiCo piloted N-Drip’s technology with a handful of farmers in India, Vietnam, and the U.S., and saw improved crop yields with less fertilizer input and 50% less water consumed versus flood irrigation.

Peter Gleick, the president-emeritus and co-founder of the Pacific Institute, a nonprofit research institute focused on freshwater issues, stresses that when it comes to the future of irrigation, it’s critical that we not lose sight of the big picture. Converting cotton or alfalfa fields to drip irrigation is a step in the right direction, but a larger question looms: Should we really be growing those crops in arid climates to begin with? “We need to have a real conversation about what it makes sense to grow in the water-scarce West, as well as a conversation about growing what we choose to grow more efficiently and more carefully,” he says. “This technology might help with the second question, but it’s not going to help with the first, more political one.”

Gleick notes that it’s one thing to object in principle to using precious drinking water to grow crops for animal feed, and another to tell farmers they should stop cultivating. Back at CRIT Farms, Moore says he’s happy to be contributing to research he sees as vital to agriculture’s future in the region. Next year he plans to use N-Drip’s system on additional acreage. Although the tribes’ reservation hasn’t had its water quota reduced, Moore knows that shortages will come for everyone one day. “We need to start living like we’re affected by those cutoffs to buy us some time,” he says. “To survive as a people, and as a business, we need to be looking at technologies like this.”

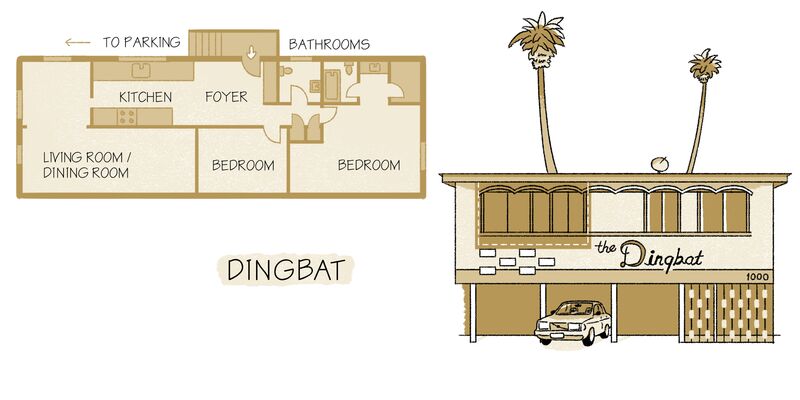

The Hauser, a “dingbat” apartment building in the Mid-City neighborhood of Los Angeles. The distinctive low-rise structures were built in the 1950s and ’60s to accommodate a boom in upwardly mobile Angelenos — and their cars.

Faced with a housing shortage, Los Angeles once had a solution. From the San Fernando Valley to Culver City to La Cienega Heights, developers in the 1950s and ’60s tore down thousands of older buildings and filled in virtually every square foot with aggressively economical two- or three-story apartment complexes — known locally as dingbats.

Subdivided into as many units as the lots could accommodate — usually between 6 and 12 — most of these stucco boxes left little room outdoors, except for an exposed carport slung beneath the second floor. This new format for affordable multifamily living became nearly as ubiquitous as the single-family tract housing that iconified the much-mythologized Southern California suburban lifestyle.

British architecture critic Reyner Banham popularized the term, which both captures the buildings’ somewhat addled appearance and riffs on the ornamental glyphs used by typesetters. But dingbats did provide an essential resource for a growing city: Los Angeles County added more than three million residents between 1940 and 1960, thanks to job booms in manufacturing and aerospace, educational opportunities for returning GIs, and the lure of year-round sunshine. Construction raced to keep up, with more than 700,000 housing units built countywide in the 1950s. New highways allowed much of this growth to sprawl into the suburbs: Vast numbers of cookie-cutter homes replaced citrus groves and ranchlands, sold as one’s own little slice of Elysian movieland, complete with driveway and pool.

Dingbats were a multifamily answer to that single-family template: Often built by small developers and mom-and-pop property owners who lived in the back, they were designed to house single people, young couples, and other upwardly mobile new residents, of which there were many. They also uniquely captured the mix of sun-drenched fantasy and hard-edged reality that remains integral to the city’s essence — after all, no place can stay a paradise forever when you actually live there.

In his path-breaking 1971 appraisal of Southland urbanism, Los Angeles: The Architecture of Four Ecologies, Banham called them “the true symptom of Los Angeles’ urban Id, trying to cope with the unprecedented appearance of residential densities too high to be subsumed within the illusions of homestead living.” Now, as 21st-century problems call for revising that suburban dream, the dingbat holds timely lessons within its stucco walls.

The first of those lessons might be that aesthetics aren’t everything. Invariably rectangular, flat-edged, and built of the cheapest materials, dingbats are unapologetically utilitarian. Yet they are anything but blank-faced. Many prominently display a single ornament, such as a starburst or boomerang, or feature decorative trimmings with a Tiki, French Chateau, or Space Age aesthetic. Pastel paint jobs are common, as are aspirational building names splayed on giant signage legible from passing cars. Such affectations could be seen as mirroring the city’s reputation — fair or not — as a land of artifice.

“They’re stylistically diverse with exotic names, but they present as what they aren’t,” said Thurman Grant, co-editor of Dingbat 2.0: The Iconic Los Angeles Apartment as Projection of a Metropolis. “It is literally a dumb box with as many units packed in as possible, with a slapped-on facade.”

The emphasis on efficiency does not stop once inside. Little space is wasted on interior walkways or common areas, though some have small courtyards or in rare cases, swimming pools. Units usually are one or two bedrooms, with truncated hallways and kitchen areas that open up to living-dining rooms. Apartment layouts vary depending on where space was available. “You get a lot of weird, L-shaped configurations to squeeze in stuff around the carport,” said Joshua Stein, co-editor of Dingbat 2.0. “Or sometimes the carports themselves couldn't be full-width.” That often meant poor airflow and thin walls and ceilings.

Many Angelenos considered these new constructions a visual blight, and still do. Before Banham, the dingbat moniker was already in use as a pejorative, including in reference to low-quality, ugly construction. California historian Leonard Pitt once wrote that “the dingbat typifies Los Angeles apartment building architecture at its worst.”

Yet like a species that adapts to its environment, dingbats were a response to the demands of their moment. City zoning codes required only one vehicle space per housing unit of more than three habitable rooms, which allowed for the dingbat’s relatively modest parking footprint at grade level (this would change after increased parking minimums and other development restrictions made dingbats less economical to build, as the architectural historian Steven Treffers has noted). In the age of the automobile, they gave lower-income households a foothold in the California suburb-scape, with some of the same cheery trimmings as single-family homes but at a price many could afford.

“They were this perfect confluence of the need to build increased density in established neighborhoods while also housing your car,” said Adrian Scott Fine, senior director of advocacy at the Los Angeles Conservancy. “They were affordable to a lot of people who couldn’t buy their first house yet or were waiting to be discovered as actors. It was housing for where you start, but hopefully not where you end.”

Today, dingbats remain a bastion of relatively affordable shelter in a city where more than 57% of renters were considered cost-burdened as of 2017 and new housing construction has slowed to a trickle. Their age means that many units are rent-stabilized, and their less-than-camera-ready appearances limit prices to some extent. Life inside a dingbat (like the one in which the author lived circa 2013) is still often characterized by stuffiness, street noise and overheard voices; during earthquakes, there’s an unsettling amount of shaking, thanks to the soft-story carport construction. (That said, dingbats have seen a wave of recent retrofits with strengthened seismic codes).

Yet plenty of Angelenos appreciate dingbats for their retro aesthetics and enduring amenities; some are even remembered fondly for star turns in movies like The Karate Kid and Slums of Beverly Hills. The small number of units in each building (complexes often come in “six pack” and “twelve pack” configurations) and tight layouts makes them great for getting to know your neighbors. Mike Farnan, a film editor who has lived in his West Hollywood dingbat since 1994, said that was a major plus during the pandemic, when the only people he saw for many months were the other tenants in his building. The fact that there wasn’t much of a shared yard didn’t matter.

“One couple and their roommate took to hanging out in the carport for socially distanced cocktails,” he said. “We’d get to chat with people who’d come by walking their dogs.” Many dingbats were built into walkable neighborhoods that predate the domination of the car, something that remains desirable today.

As the city has grown, observers say that the profile of dingbat residents has shifted. Newcomers from all over the world have made their homes within the zig-zagging floorplans as the city swelled with immigrants. With housing prices soaring, it’s likely that more tenants are staying put rather than moving up and out. “To me it seems like the set of inhabitants is almost as diverse as the city itself,” Stein said. “And while it used to be all about upwardly mobile folks, that may no longer be the case.”

Dingbats may also hold the possibility for accommodating further infill: Thanks to recent legal changes, it’s now possible to convert carports into accessory dwelling units, which some owners are beginning to do.

More than that, dingbats hold lessons for modern Angelenos: They tell a story of when the city met the demands of the day with a low-cost, replicable, yet individualized housing form factor. Stein and Grant’s Dingbat 2.0 book — a collection of essays, photography, and diagrams — was the culmination of a 2010 design competition sponsored by the Los Angeles Forum for Architecture and Urban Design that called for a new housing typology for Los Angeles that could meet the new century’s demands for density while staying true to the urban fabric. A more recent contest sponsored by the city to generate “missing middle” housing ideas shows that the needs are only growing stronger, between the unsustainability of suburban sprawl in the face of climate change and a homelessness crisis.

“We put forward the dingbat as something that reshaped L.A. and made it what it is,” Stein said. “The future of the city will be dependent on what comes after it.”

Comments

Post a Comment